Electronics and PCB design

Electronics design and PCB (Printed Circuit Board) design involve a series of crucial steps that Iron Wolf Enterprises follows to create efficient and reliable electronic systems. Here are the key stages in the electronics and PCB design process:

Requirement Analysis

Iron Wolf Enterprises begins by understanding the client’s requirements and specifications for the electronic system. They work closely with the client to identify the desired functionalities, performance criteria, and any specific constraints. Through thorough requirement analysis, Iron Wolf Enterprises ensures a clear understanding of the project goals before proceeding to the design phase.

Schematic Design

In this phase, Iron Wolf Enterprises creates the schematic diagram, which serves as the blueprint for the electronic system. They carefully select and integrate components such as integrated circuits (ICs), resistors, capacitors, and other electronic elements to ensure the desired functionality. The schematic design captures the interconnections and relationships between the components, forming the foundation for the PCB design.

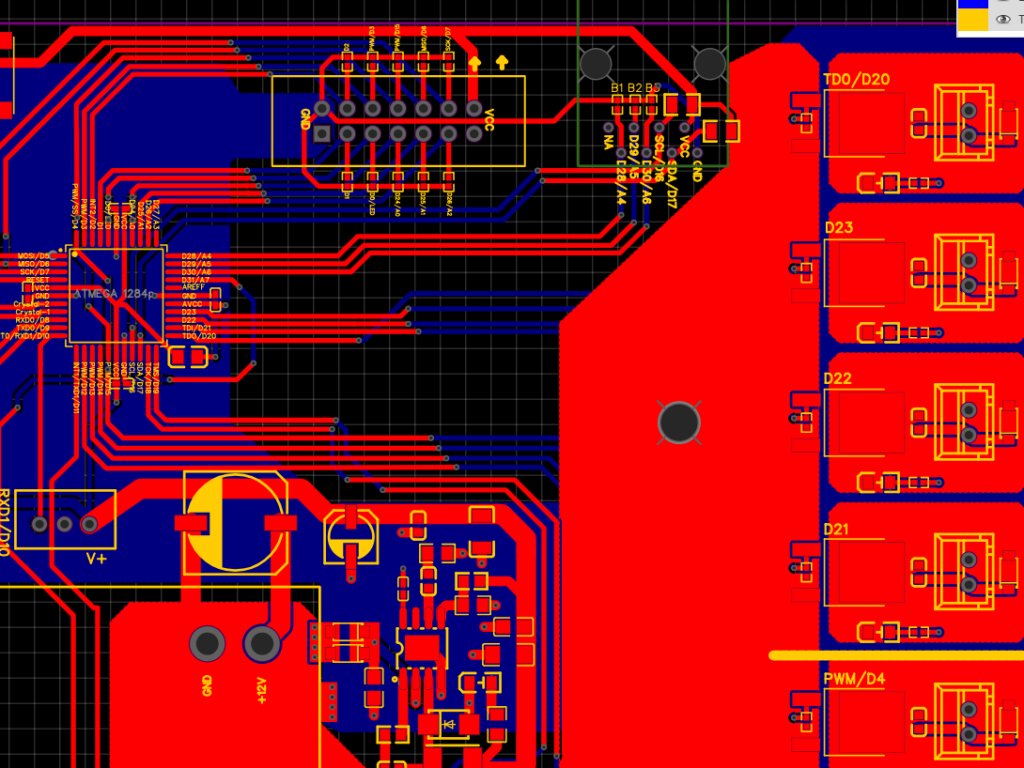

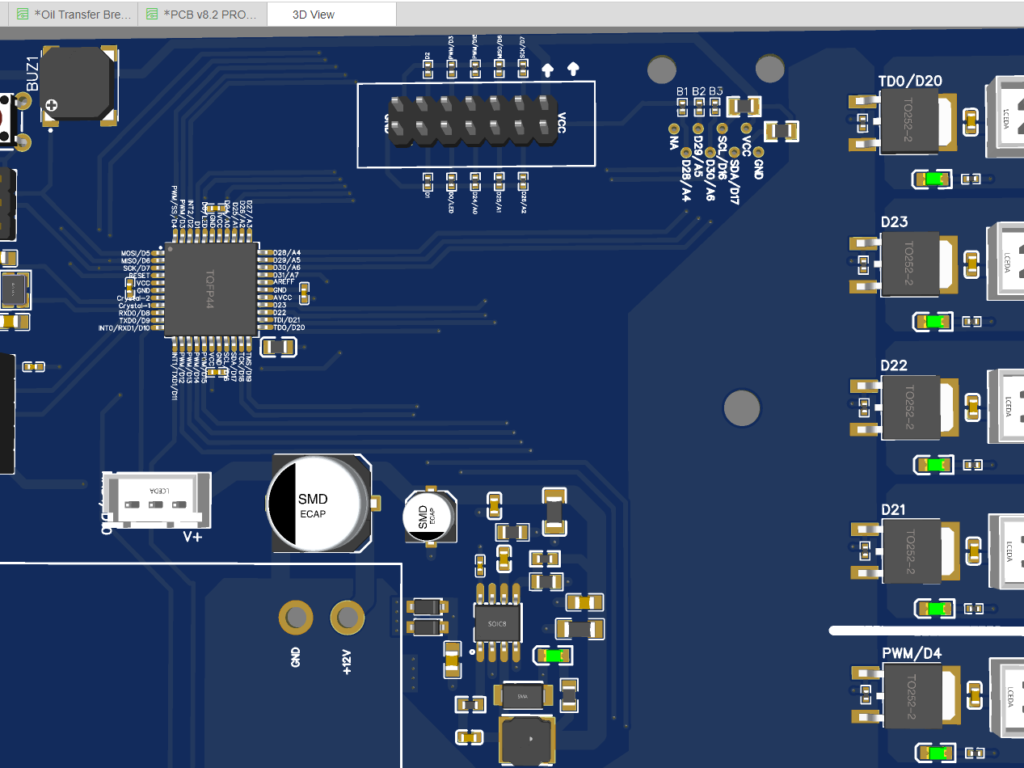

PCB Layout Design

Based on the schematic design, Iron Wolf Enterprises proceeds to the PCB layout design. They utilize specialized software to arrange the components on the PCB, considering factors like signal integrity, power distribution, and thermal management. Iron Wolf Enterprises focuses on optimizing the layout for efficient signal flow, minimizing noise, and ensuring manufacturability. Attention is given to proper component placement, routing, and layer stackup to meet electrical and mechanical requirements.

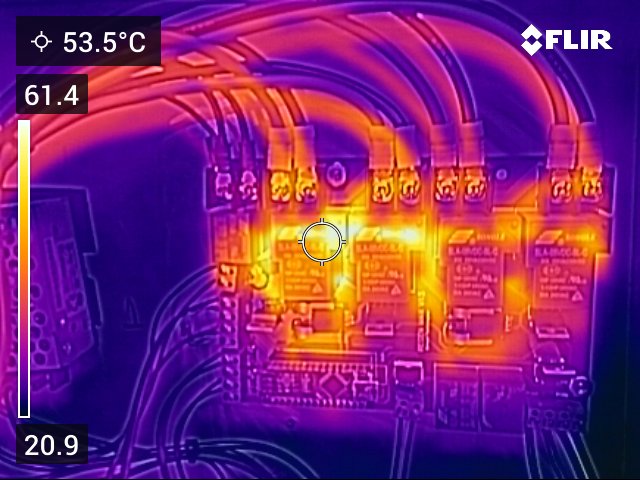

Design Verification and Simulation

Iron Wolf Enterprises conducts design verification and simulation to ensure the functionality and performance of the electronic system. They utilize simulation tools to analyze signal integrity, power integrity, and thermal characteristics of the PCB design. Through simulations, Iron Wolf Enterprises identifies potential issues and optimizes the design to meet the desired specifications.

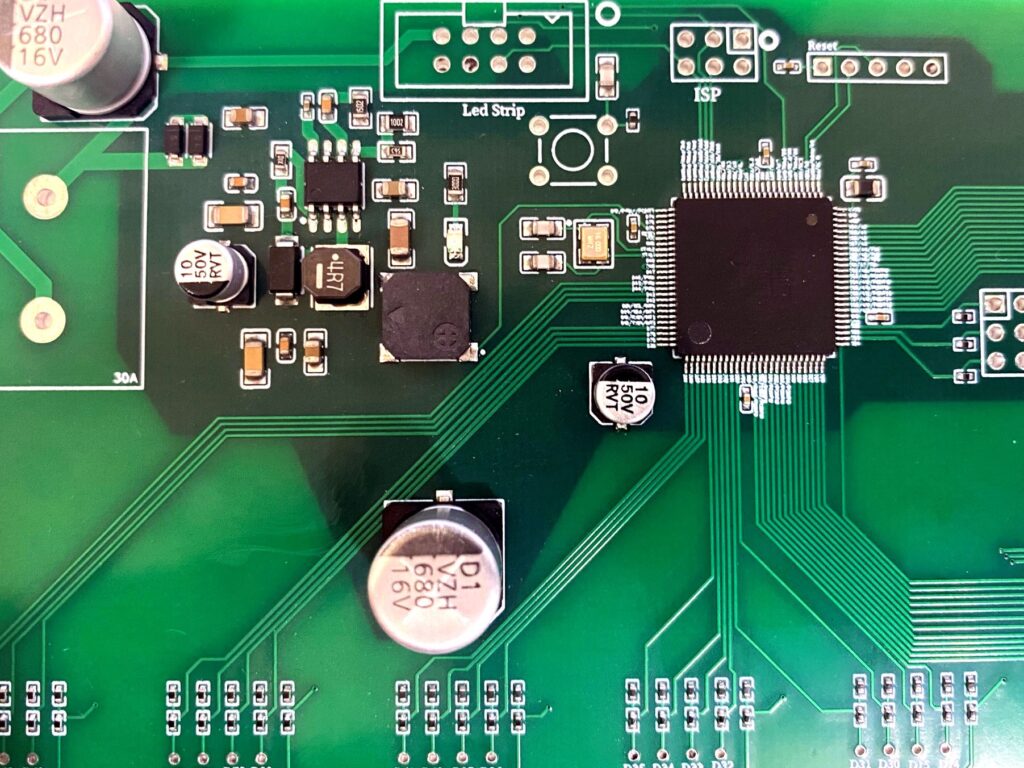

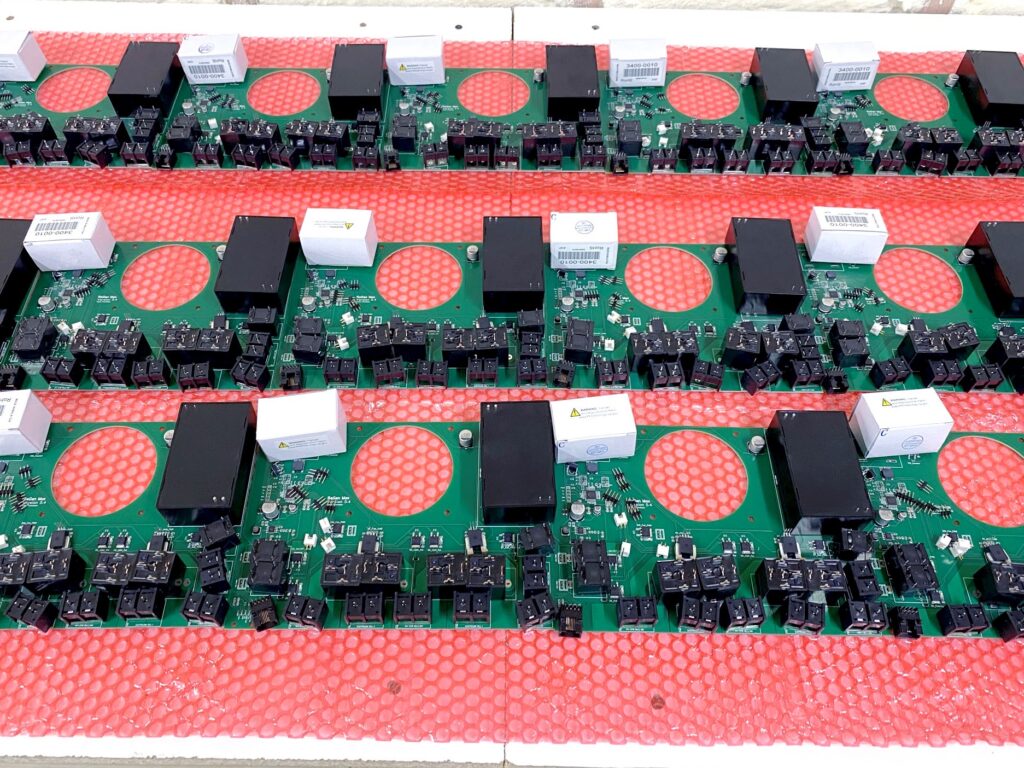

Prototyping and Testing

Once the PCB design is verified, Iron Wolf Enterprises moves on to prototyping. They manufacture a small number of PCBs to build functional prototypes of the electronic system. Rigorous testing is performed on the prototypes to validate the design, identify any issues, and make necessary refinements. This iterative process ensures the PCB design meets the required performance, reliability, and functionality standards.

Manufacturing Support

After the prototype is successfully tested and refined, Iron Wolf Enterprises provides manufacturing support. They work closely with manufacturing partners to ensure a smooth transition from prototype to production. Iron Wolf Enterprises assists in the selection of suitable manufacturing techniques, materials, and assembly processes, considering factors like cost-effectiveness, scalability, and quality control. They also provide guidance on design for manufacturability (DFM) considerations to optimize the production process.

Throughout the electronics and PCB design process, Iron Wolf Enterprises maintains active collaboration with clients, keeping them informed about design progress, seeking their input, and ensuring alignment with their expectations. Their expertise in each step of the process enables them to deliver efficient, reliable, and high-performance electronic systems that meet industry standards and client requirements.